LaserDraw is developped and utilized in CO2 laser engraving machine with B1 motherboard.

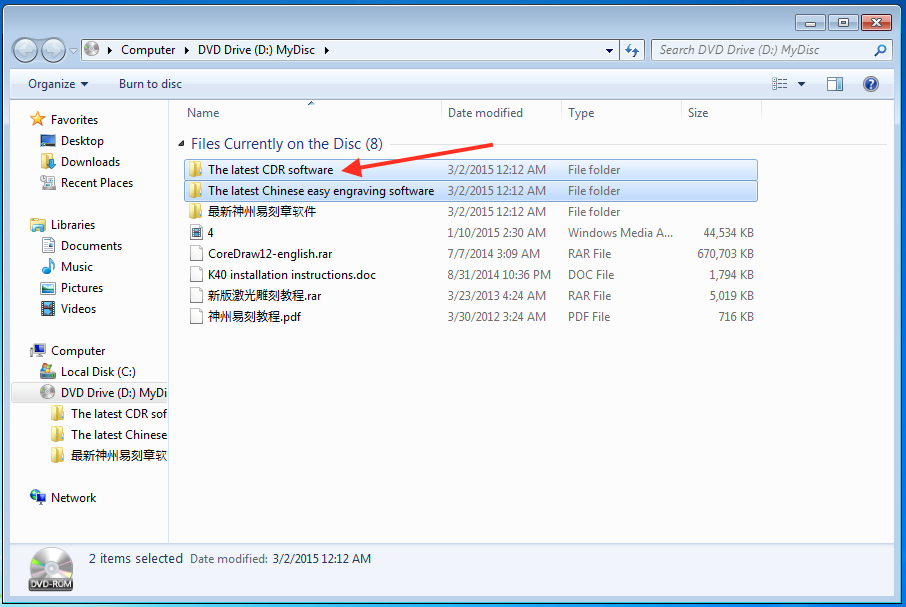

(1) Double click this icon to open the software,it will open Coreldraw,then you can see our software tool bar in Coreldraw,as showing: (2) Then click this button to set Engraving machine properties,as showing: Here we need to set the same setting for Mainboard as the picture above showing,set PageSize. (1) Double click this icon to open the software,it will open Coreldraw,then you can see our software tool bar in Coreldraw,as showing: (2) Then click this button to set Engraving machine properties,as showing: Here we need to set the same setting for Mainboard as the picture above showing,set PageSize. Control software for the stock K40 Laser controller Contents Background Features Supported Controller Boards Changes Download Documentation Related Links Background K40 Whisperer is an alternative to the the Laser Draw (LaserDRW) program that comes with the cheap Chinese laser cutters available on E-Bay and Amazon. LaserDRW 2013.02 is a Shareware software in the category Graphics Applications developed by LiHuiyusoft Co., Ltd. It was checked for updates 283 times by the users of our client application UpdateStar during the last month. The latest version of LaserDRW 2013.02 is 51.1052, released on. It was initially added to our database on 02.

LaserDraw is very basic software for Chinese Made CO2 laser engraving machine. However, this tool is quite strong accept vector file like WMF to support large scale(1.6m) Cut/Engraving job.

Laser Engraver Setting is first step to enable working.

Hardware initialize

Mainboard: Please make sure LASER-B1 is selected.

SpeedRatio: It means flexible speed when trend/direction of engraving changed too quick eg. sharp curve, as sequently engraving effect is smoother than fixed speed. keep it as auto.

Resolution: 1000 DPI is standard. keep it no change.

Max Speed: Keep it as 500mm/s as well

Coordinate: Machine coordinates. It includes a few options. In sake of operation habit, we always use top left.

Logic page initialize

Origin -X: it is home for x under machine coordinates

Origin -Y: it is home for Y under machine coordinates

PageSizeX: Drawing table size of engraving machine for X

PageSizeY: Drawing table size of engraving machine for Y

Mainboard initialize

Device ID: it is 16 digit number(input correctly to drive machine)

Adjust thread priority:

Priority: Currently, computer running speed is very fast. It doesn’t matter and keep it as is.

Adjust retrace feature

Amend: this works only in case of engraving from dual sides. Keep it as is.

Running in adjustment: In situation of the laser engraving machine works for a long time, some parts reach life span and get replaced. The new parts need runing in to become working smoothly. When you get machine in new status, don’t need have to do because it is done before leaving factory.

Control for adjustment: keep it as is.

Engraving Manager

Rotate: it works when using A Axis engraving

Style:

Engraving: It divides normal and sunken. Normal, laser scans area except drawing. Sunken, laser scans area of drawing. Most of time, sunken was used. Speed range from 300 to 500mm/s.

Cutting: It includes 6 cutting routing process options. Cutting routing process is greatly importance on top of depth and speed.

As drawing

As layer

Small -> Large

Large -> Small

Inside first

Shorteset route

Cutting speed: range from 15 to 30mm/s

Neareset: This option improve efficience a lot. It ask laser head to cut from nearest position(NOT starting potion of each drawing) eg. In CorelDraw, it draws graphic starting from left-bottom.

Marking: Working mode is similar to engraving(sunken) and maching effect is better than. This function is rarely used because CO2 laser engraving machine speed is too slow. Laser marking machine use Galvanometer which provide much quick speed 5000+

Common Parameters

JoinGap: This function works only in engraving(normal) mode. It mainly use in engraving stamps.

Refer- X: Coordinates for Refer-X

Refer- Y: Coordinates for Refer-Y

Advanced Parameters

Method: In below diagram, it shows an example how to use method dialog and all layers(and relationship). This function is important to multi-task for efficiency improving.

Pixel: Default setting is 2 steps. eg. machine resolusion 1000DPI and engraving resolusion is 1000DPI/2=500DPI

Repeat: Repeat time of one task. Principle is similar to method(dialog). In situation of cutting much thicker material or mass production, this function is quite useful.

FAQ

1.Q: Why my laser engraving machine was disconnected to computer?

A: Motherboard divide into different models eg. A/B/B1/M/M1. Please check and select correct one. Then, 16 digit regristration number should be input correctly.

2.Q: My size in design is 10″x10″. Why laser cutter cut 20″x20″?

A: This problem caused by logic resolution. Default resolution is 1000 dpi. eg. The design output from Coreldraw is 1000dpi, and machine setting is 2000dpi. Laser engraving machine will cut/engrave twice than defined.

3.Q: What Max. speed of this laser engraving machine?

A: Machine with B1 is 500mm/s, commonly run at 300 to 400 at engraving and 15 to 30 at cutting.

4.Q: Where is origin point?

A: Machine origin point is on left-top but subject to change according to software.

5.Q: Why is laser head moving up and down while drag design left and right?

Corellaser Laserdrw Software Download Vidmate

A: laser head is on X Axis horizontal move. Don’t check box laser head vertical move.

6. Q: Why laser engraver registration fail?

A: Please refer to Question No.1

Corellaser 2019

7. What is difference between machine coordinates and workpiece coordinates?

K40 Corellaser Download

A: Machine coordinate is fixed and depend on machine size. Workpiece coordinate stand for area can cut/engrave. Workpiece coordinates is inside Machine coordinates.